Product Category

CASE STUDY

1

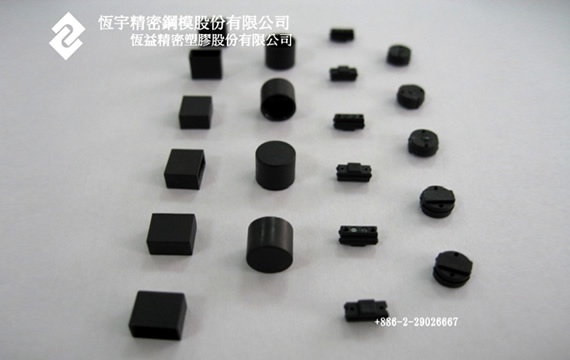

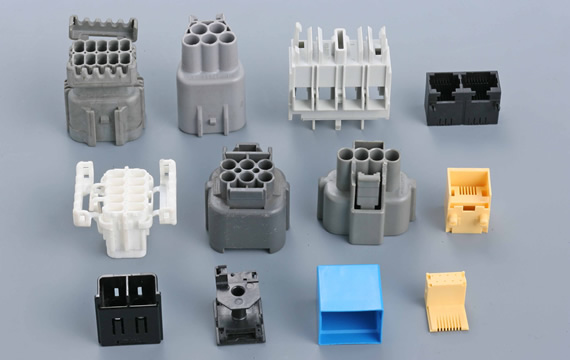

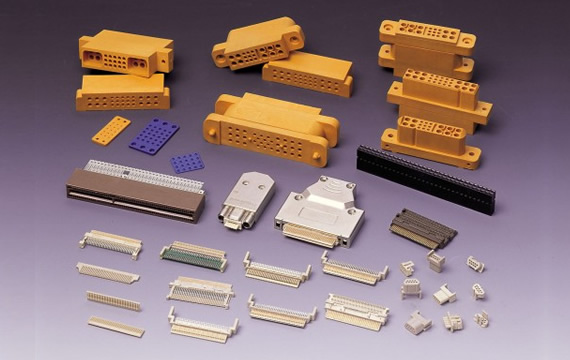

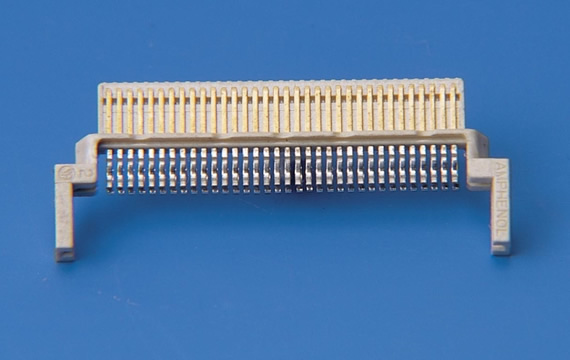

Connector Series

Our unique mold opening method uses a special mold structure design to overcome difficulties faced during mass production; the functionality, reliability, and integrity of the parts produced during our molds’ first trial test is 98%, which greatly reduces the time required for product development. Examples include: multi-hole (>200 holes) connectors, SFP connector pull-tabs, and automotive FAKRA.

2

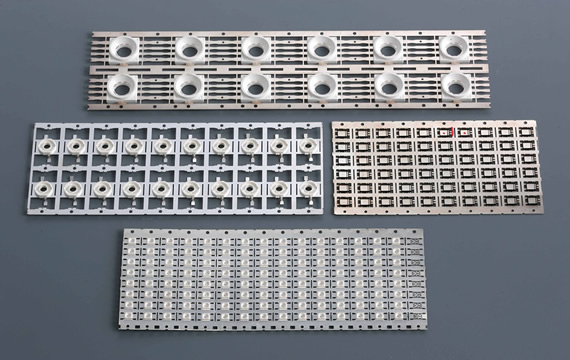

Automated Insert Molded Products

Fully automated production equipment allows us to provide customers with precision insert molded products; reel-to-reel insert molded products are competitively priced and are stable in quality. Insert molded products include SMD LED lead frames and electronic parts and components.

3

Medical Products

Each product is monitored via a unique serial number, batch tracking and SFP system for real-time information on production process and progress. Product categories include safety needles, microsurgical parts, nasal washers, and specimen analysis equipment.

4

Stylus Pen

We provide a full range of solutions, from the stylus tip, stylus body, stylus casing and other parts, from insert molding to assembly, printing and spray coating to deliver the finished product.

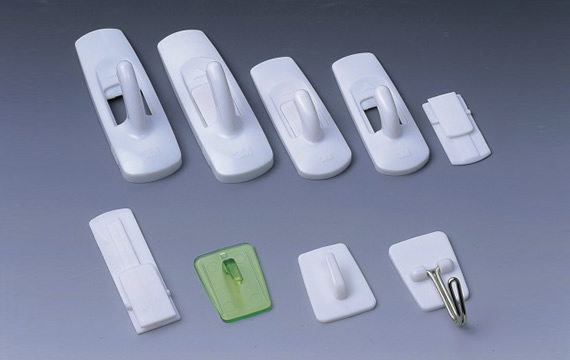

5

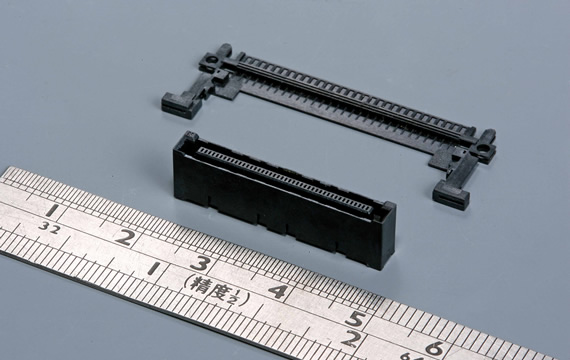

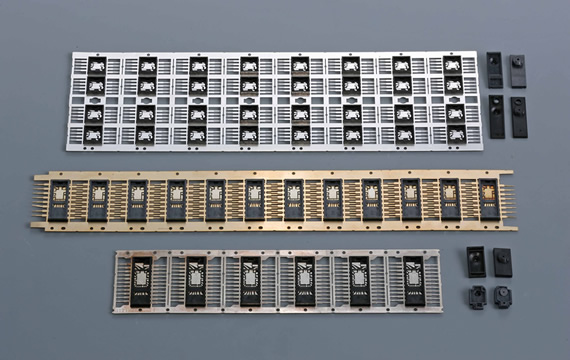

Manual Insert Molded Products

Multi-hole design, 68-pin insert molded. Many pitches spread over a small diameter length requires high-precision molds. We use jigs and other auxiliary tools to increase production efficiency.

6

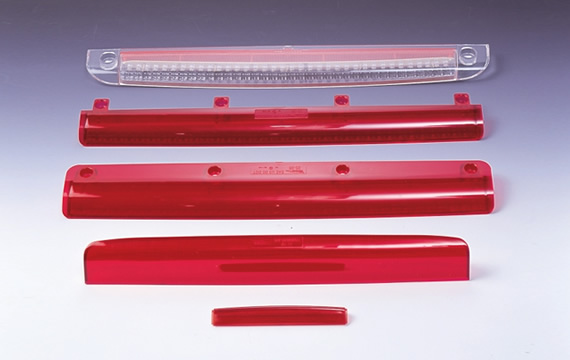

Plastic Injection Molded Casings

High-specification surface treatment technique. Uses mold flow analysis and mold structure adjustments to overcome problems related to product appearance. Eliminates flow lines and weld lines. We also produce casings with mirror-polished surfaces to meet customer expectations.

7

Optical Lens

Mold has a tolerance of less than 0.5um, with a mirror-polished surface to meet customer expectations. Products are widely used in gaming mice and optical lenses.

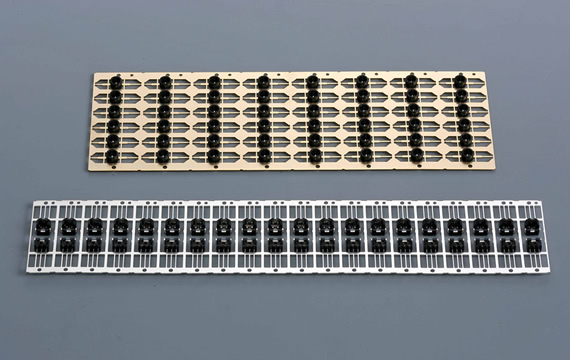

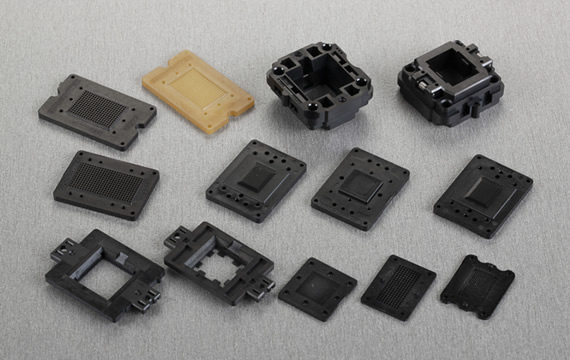

8

Semiconductor Series

Requires a high-precision mold. Our socket series can produce 256-hole, 0.5mm pitch, with hole measurements of 0.17x0.24x0.33mm; the distance between holes (wall thickness) can be as fine as 0.05mm. We can send samples from the first mold test.

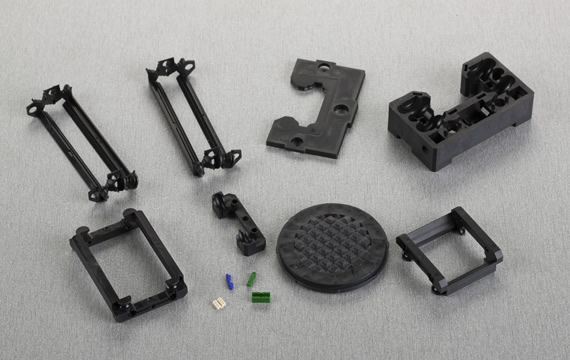

9

Mechanical Products

High wear resistance engineering plastics are used to make high-precision molds. Our silent-type plastic chain can be as thin as 0.5mm. Screw threads are automatically formed via high-temperature plastics and in-mold threads, reducing second processing costs. Our understanding of the raw material characteristics of engineering plastics allows us to come up with good mold structure designs for maximum economic benefits. At present, Endeavor Plastics can make injection molding products of 0.76mm diameter with a thread of 7 starts.

10

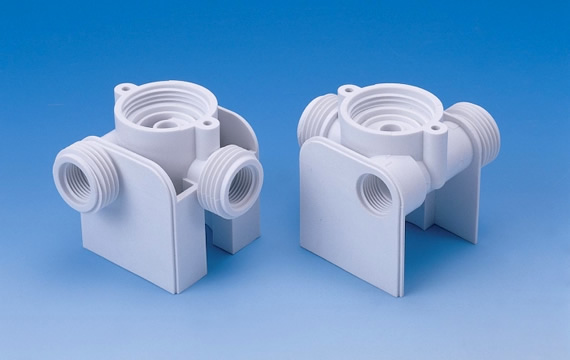

Valve Series

The four-way valve (complete with threading) is designed to be fully formed upon ejection, without the need for post processing to save processing costs. Water valves experience high water pressure, and our valve boss can be precisely processed to achieve airtightness and watertightness.

.jpg)

.jpg)

.jpg)