Vertical Integration

Endeavor Plastics insists on providing cutting-edge precision technology in the field of plastic injection. Endeavor Plastics is committed to the process of vertical integration in the plastics industry, providing customers with a diverse range of choices that goes beyond mold development and plastic injection to include secondary processing of plastic parts, full inspection and shipment. We are committed to safeguarding the quality of our customers' products and providing the best and most comprehensive range of services.

Mold Design and Development

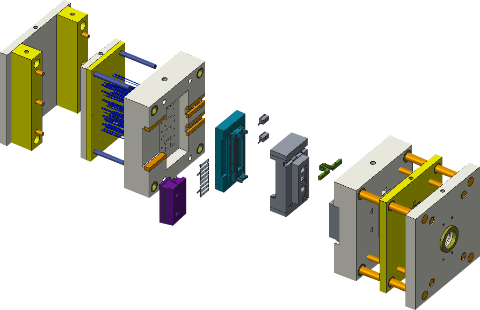

Endeavor Plastics has an excellent engineering and research team with over 30 years of rich experience in mold design and plastic mold injection; the team also has professional research capabilities in the field of plastics material to meet various existing demands, such as high precision, high specifications and high-quality requirements.

R&D Software:

- AUTO CAD

- Creo Parametric

- SolidWorks

- SolidWorks CAE

- CIMATRON

Combining professional demolding technology and mold flow analysis, we provide high-precision mold structure designs and can simulate various defects and problems that may occur in the finished product before the mold fabricate. We provide Design for Manufacturability (DFM) feedback in the early stages which reduces the cost and time taken for mold development.

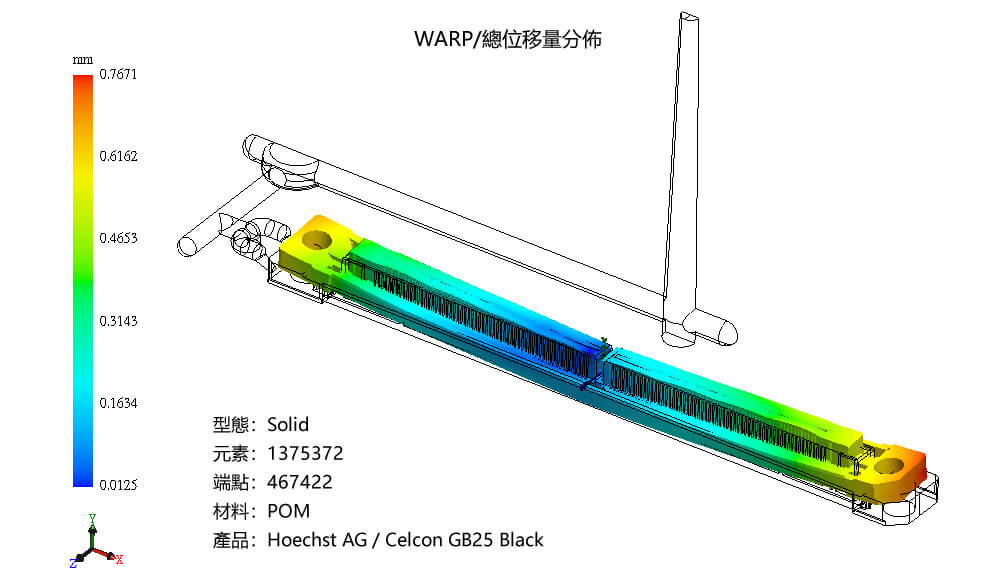

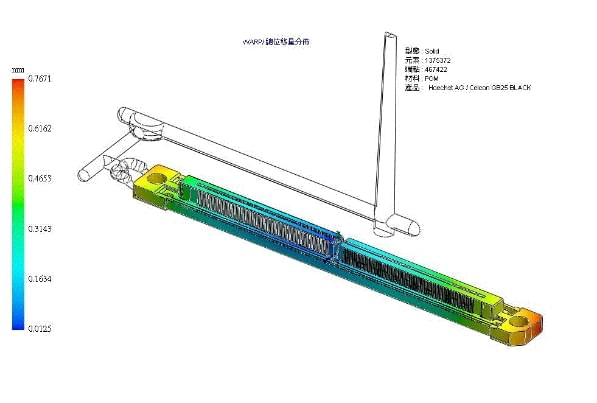

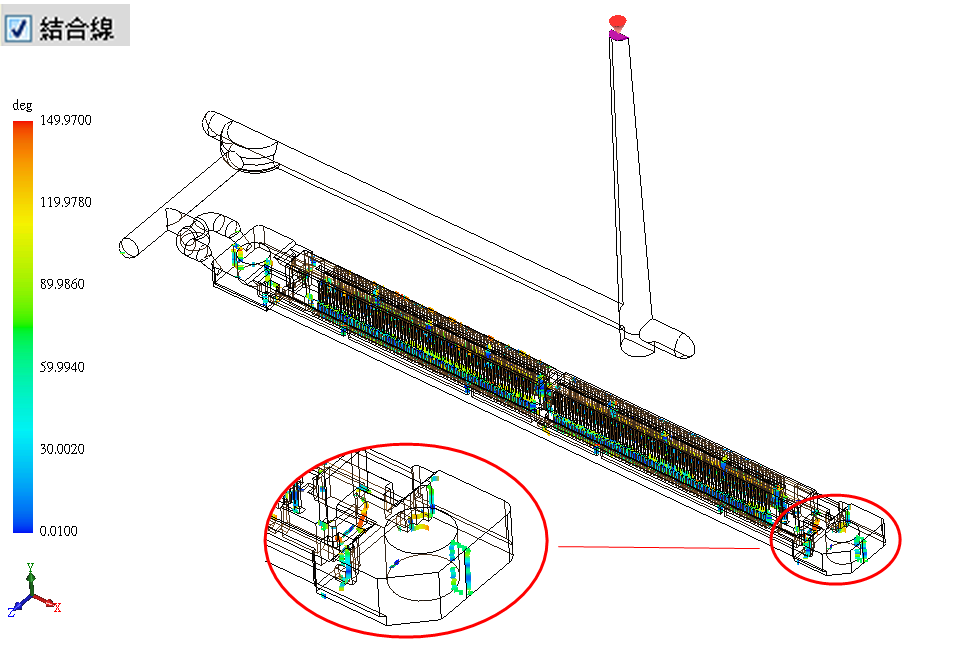

More Process PhotosMold Flow Analysis

Mold flow analysis allows us to predict the occurrence of defects that may occur during the injection molding process, such as: deformation, short shot, vacuum void, warpage and weld lines; Endeavor Plastics can identify the weakest points in a finished product and give recommendations on how to improve its structure.

The ability to foresee problems allows us to present holistic solutions backed by data. The optimization of mold and product strength greatly reduces costs of development and enhances product stability during mass production.

Mold-Flow Analysis Case

Plastic Injection Molding

Endeavor Plastics specializes in working with various engineering plastic materials, such as: PEEK, ULTEM, NYLON, PBT, PPS, high-strength high-rigidity fiberglass, and other advanced raw materials. Endeavor Plastics is also actively engaged in the research and development of highly complex, high precision optical products, medical products and products used in fiber optic transmissions.

Our factory has modern plastic injection molding equipment and automated production technology. Production data is recorded via a monitoring system that uses data analysis to optimize process capabilities from small-batch trial run to mass productions, to provide customers with reasonably priced and economical products.

.png)